Why AMRs / AGVs Need the Right Manipulator - and how OMY fits

Posted by Mason Knittle on 13th Nov 2025

Mobility made robots useful. Manipulation makes them indispensable.

Learn why the manipulator is the real bottleneck for mobile automation, and why OMY was built to remove it.

Why Manipulation Matters for Mobile Platforms

Automated Guided Vehicles (AGVs) and Autonomous Mobile Robots (AMRs) are increasingly being adopted at scale in warehouses and on factory floors. AGVs typically follow fixed paths or tracks, using rails, magnetic strips, or pre-programmed routes, making them reliable for transporting pallets, carts, or materials from one location to another. AMRs, in contrast, are more flexible. They use onboard sensors, cameras, and AI to navigate dynamically, handling changing environments and avoiding obstacles without human intervention. In both cases, mobility is their primary strength, wheels give these robots the freedom to move efficiently across complex spaces.

The truth is that many AMRs today excel at transport; moving bins, carts, or pallets. However, the next step in warehouse and high-value automation comes from adding manipulators, or robotic arms, that enable these platforms to interact with objects. Manipulation opens up new workflows such as true bin picking, machine tending, order fulfillment, inspection, and even light assembly. In other words, wheels provide freedom, but arms give purpose.

The ROBOTIS OMY was designed for those use cases. Pick-and-place, inspection, teleoperation, and learning-based policies that let a single mobile platform do more than just ferry parts.

Light-Weight: Designed for the Mobile, Unstructured World

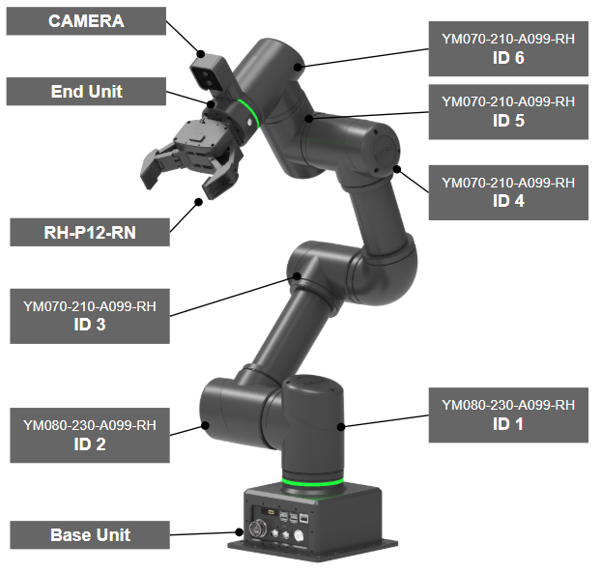

Mobile robots often have strict payload and center-of-gravity limits. A heavy arm reduces run-time, capability, and safety margins. And today, many manipulators utilize a strong, but heavy controller bock. AMRs however, need an arm light enough to not cause restriction, while still having the power and durability to withstand a days work. The OMY can excel in many instances when paired with an AMR or AGV, thanks to the manipulators current specs, such as size, light weight, and compact controller.

OMY-F3M

580 mm

13.5 kg

3 kg

Modular Design & Integration

Why modularity matters: Different tasks need different grippers, sensors, torque capacity, and safety features. A modular manipulator reduces downtime and increases reusability across fleets.

| Use Case | Why Modular Helps | OMY Fit |

|---|---|---|

| Bin picking | Custom grippers + camera placement | Quick gripper swaps + ROS 2 vision integration |

| Machine tending | High repeatability, safety interlocks, modular actuators | Brake options and precise joint control |

| Order fulfillment | Varying payloads & reach | Multiple OMY configs |

| Assembly / Inspection | Sensor & tooling changes | Sensor upgrades + simulation tests |

AMR-Ready Durability & Impact Resistance

Mobile environments are rarely gentle. AMRs operate on concrete floors, ramps, and uneven seams, carrying shifting payloads while navigating around people and equipment. In these dynamic conditions, a manipulator must endure not just the precision demands of motion control but also constant vibration, jolts, and incidental impacts. Durability here isn’t optional, it’s the foundation of uptime, safety, and long-term ROI.

OMY was built for this exact reality. Where traditional harmonic or planetary drives excel in compactness, they fall short in resilience. Harmonic drives rely on flexing metal components that fatigue and lose accuracy under repetitive shocks, while planetary gears concentrate force on small tooth surfaces prone to wear or breakage. In contrast, OMY’s DYNAMIXEL DRIVE (DYD) cycloidal reducers use a rolling contact mechanism that spreads loads evenly across multiple contact points. This design absorbs impacts, resists deformation, and maintains torque stability even under heavy, uneven, or bumpy conditions. The result manipulation that stays smooth, accurate, and reliable, long after other mechanisms would need recalibration or replacement.

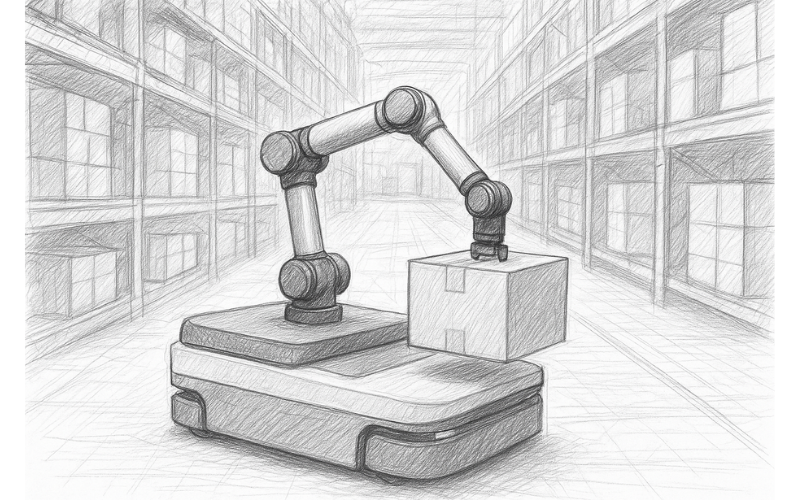

ROBOTIS DYNAMIXEL-Y actuators are the core actuators in the OMY, which integrate motor, sensor, driver, brake, and DYD cycloidal reducer into a single sealed assembly. Each joint delivers low backlash (< 3.0 Arcmin), high repeatability (±0.05 [mm]), and robust resistance to vibration or collision - performance that many lab-grade arms simply can’t sustain.

In warehouse and factory environments, durability directly translates to productivity. A manipulator that shrugs off minor collisions and keeps calibration stable means fewer emergency stops, less maintenance, and longer service intervals. When every AMR in your fleet can run for months without unplanned downtime, throughput stays high and total cost of ownership drops.

Bottom line: OMY’s combination of DYNAMIXEL-Y actuators and DYD cycloidal reducers provides the impact resistance and torque stability that real-world mobile manipulation demands. The result is a manipulator that stays precise, resists damage, and keeps AMRs working, not waiting for service.

Vision — From OMY to the “AI Worker”

When OMY-style manipulators pair with fleet-savvy AMRs and learning toolchains, you get robots that adapt and improve — the foundation of Physical AI.

Demo, ROS 2 packages, and simulation models available online.

To Conclude

Mobility got us in the door. Manipulation opens the revenue stream.

The right arm transforms an AMR from “transport only” into a multi-task worker that picks, inspects, and grows more capable as policies are learned. OMY was designed from the ground up for that job.