OMY: Durable, Flexible, and Industry-Ready Robotic Manipulation

Posted by Mason Knittle on 30th Oct 2025

The ROBOTIS OMY Leader-Follower Platform is setting a new standard in robotic arms for research, industrial applications, and intelligent automation. With its compact size, modular design, and advanced actuators, OMY provides the flexibility and precision necessary for tasks ranging from imitation learning experiments to repetitive industrial operations.

By combining durable mechanics with AI-driven control, this platform enables both physical AI research and practical deployment in factory or laboratory environments.

Compact and Flexible Design for Real-World Applications

The ROBOTIS OMY combines advanced engineering and adaptable functionality in a compact form designed for real-world use. With a 6-DOF configuration and a reach of up to 580 mm, OMY delivers a broad operational workspace while maintaining a lighter weight of 13.5 kg and 170 mm diameter footprint.

This compactness is crucial for applications in crowded laboratory settings, mobile platforms, and collaborative industrial environments, where large robotic systems would be impractical. Its small footprint allows for easy integration into existing workflows without the need for extensive reconfiguration of the workspace itself.

Precision and Reliability: DYNAMIXEL-Y Actuators

At the core of the OMY manipulator are DYNAMIXEL-Y actuators, compact yet powerful motors with integrated controllers, Drivers, Sensors, Communication Modules, Electronic Breaks, and Gear Reducers. These actuators are designed to deliver both high torque and precise, repeatable motion, which are critical specifications for for research, prototyping, and industrial tasks where accuracy matters.

OMY uses two different actuator types to balance power and precision across its 6 joints:

YM080-230-A099-RH – used in the base joints;

| Backlash | < 3.0 [arcmin] |

| Radial Load | 1,920 [N] |

| Brake type | Spring applied brake |

| No Load Speed | 32.2 [rev/min] |

| Continuous Speed | 20.2 [rev/min] |

| Continuous Torque | 26.0 [N.m] |

| Continuous Current | 10.7 [A] |

| Maximum Torque | 61.4 [N.m] |

YM070-210-A099-RH – used in the upper joints;

| Backlash | < 3.0 [arcmin] |

| Radial Load | 1,520 [N] |

| Brake type | Spring applied brake |

| No Load Speed | 57.3 [rev/min] |

| Continuous Speed | 20.2 [rev/min] |

| Continuous Torque | 14.6 [N.m] |

| Continuous Current | 11.0 [A] |

| Maximum Torque | 31.7 [N.m] |

These actuators are not just reliable, they’re proven. They’re also used in the ROBOTIS AI Worker semi-humanoid platform, highlighting their durability in complex, multi-joint systems. For OMY, this means smooth, precise motion, repeatable performance, and flexibility across a wide range of applications—from delicate lab experiments to automated assembly and collaborative robotics.

How DYNAMIXEL-Y Encoders Achieve Ultra-High Precision

The OMY manipulator’s precision comes from the DYNAMIXEL-Y actuators, which combine high-resolution encoders with internal gear reduction and multi-turn tracking. Here’s how it works:

524,288 pulses per motor rev (19-bit single-turn encoder)

51,904,512 pulses per output revolution

~13.6 billion unique positions tracked over multiple turns

Key Points

- Single-Turn Encoder (19-bit, 524,288 pulses/rev) – Measures precise rotation of the motor shaft.

- Gear Reduction (99:1) – Each output shaft revolution equals 99 motor revolutions, giving 51,904,512 pulses per output revolution for smooth, repeatable motion.

- Multi-Turn Encoder (18-bit, 262,144 revolutions) – Tracks absolute position over many turns, resulting in a total position range of ~13.6 billion steps.

Takeaway for OMY Users: The actuators’ high resolution allows sub-millimeter precision even at full extension, while multi-turn tracking ensures accurate absolute positioning. This combination of compact, high-precision actuators with internal gear reduction is what makes OMY both small and extremely capable.

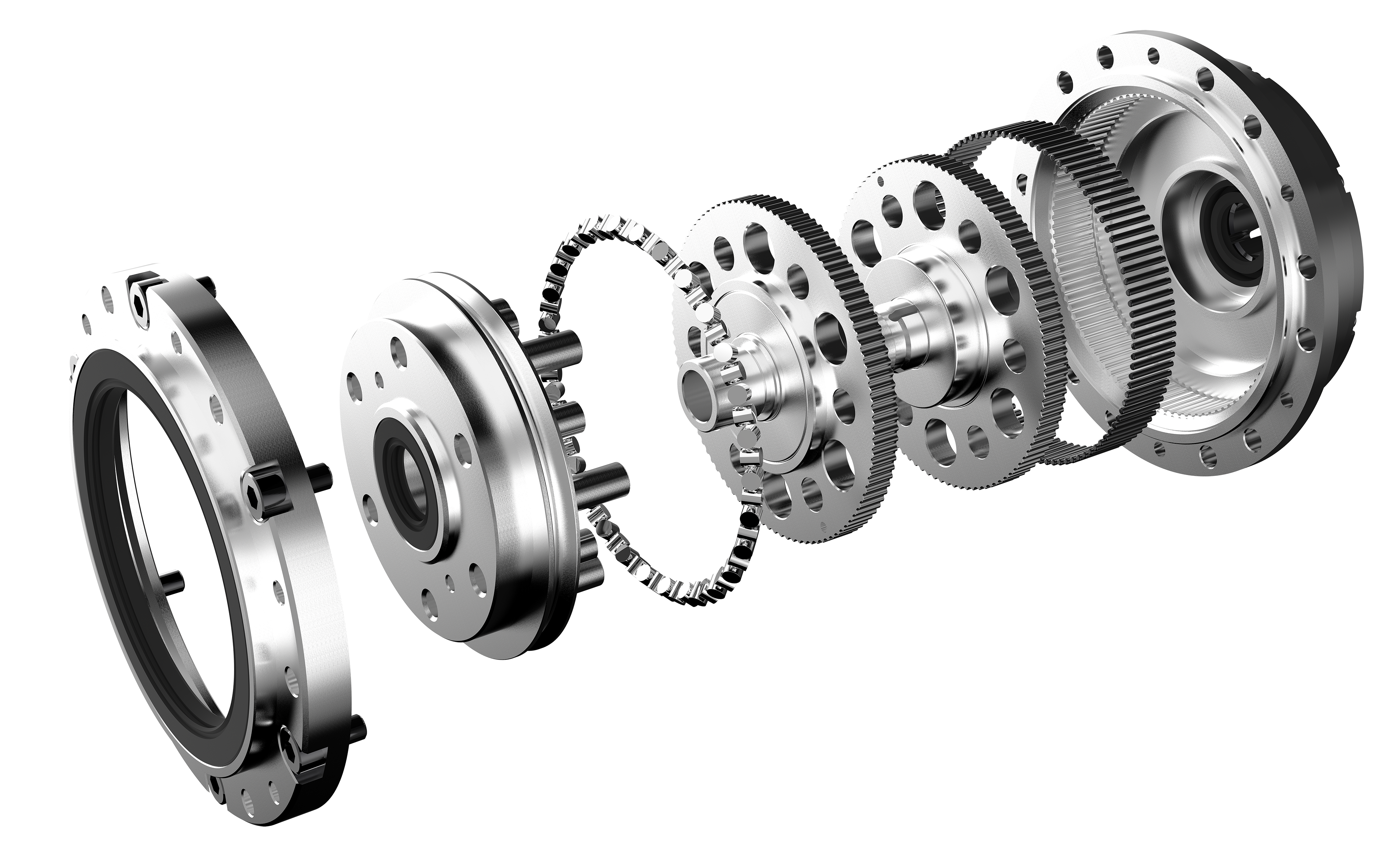

Durability Through Cycloidal Gear Reduction

The DYNAMIXEL-Y actuators that power each OMY joint use cycloidal gear reduction which is a high-performance transmission technology designed for exceptional torque density, low backlash, and long service life. Unlike traditional planetary or harmonic drives, which rely on tooth-to-tooth meshing or elastic deformation, a cycloidal reducer transmits motion through multiple rolling contact points between the cycloidal disc and its pin followers.

Key Advantage: This distributed load path allows each contact point to share torque evenly, reducing surface pressure and fatigue. Cycloidal drives can handle shock loads exceeding well above their rated torque without permanent deformation or tooth breakage.

This structural redundancy is a key reason why the DYNAMIXEL-Y actuators inside OMY remain stable and precise even under sudden impacts or dynamic load conditions that often cause backlash growth or failure in planetary and harmonic systems.

Cycloidal reducers also exhibit rolling instead of sliding friction, which minimizes wear and heat generation during rapid or repetitive operation. Studies show that a well-engineered cycloidal reducer can last 5–10× longer than most harmonic and planetary counterparts. Combined with the rigid, non-flexing construction of the DYNAMIXEL-Y housing, OMY’s joints achieve exceptional torsional stiffness and impact resistance, ensuring stable positioning even after collisions.

Real-World Reliability

In practice, OMY can safely absorb unplanned forces — such as collisions during teleoperation or contact in collaborative tasks — without damaging its internal gearing or losing calibration. That resilience is vital in industrial and research environments where reliability, uptime, and safety are critical.

Together, the cycloidal reduction mechanism and DYNAMIXEL-Y’s integrated encoders, brakes, and control electronics make OMY a robotic platform that blends precision, endurance, and robustness. This makes it ideal for delicate assembly, repetitive motion, and human-robot collaboration — where consistent accuracy and safety must coexist.

Modularity and Ease of Maintenance

Every joint of the ROBOTIS OMY is built as a fully self-contained DYNAMIXEL-Y module — a complete unit that integrates motor, driver, sensors, communication, and control electronics into a single, compact housing. This modular architecture is what gives OMY its unique ability to evolve, adapt, and stay ahead of the curve.

Built for Customization

- Swap Actuators: Engineers can easily exchange joint modules (e.g., YM070-210 or YM080-230) to balance torque, speed, or weight for different applications.

- Add Sensors: Attach vision modules, force-torque sensors, or proximity systems to enable advanced interaction and precision feedback.

- Change End-Effectors: Quickly integrate grippers, suction tools, or custom manipulators for specialized lab or industrial workflows.

This level of modularity means rapid reconfiguration — an essential advantage for research teams and developers who need to experiment with different hardware setups. Whether testing new control algorithms, training an AI model through imitation learning, or deploying a production-ready manipulator, OMY’s design adapts seamlessly.

Low Maintenance, High Uptime

If a component ever requires service, only the affected DYNAMIXEL-Y actuator needs replacement — not the entire arm. This reduces downtime by up to 80% and minimizes maintenance costs. The plug-and-play modular design also simplifies diagnostics, since each actuator reports its own health, temperature, and torque data in real time via RS-485 or TTL communication.

As new actuator generations or sensor modules are released, the OMY platform can evolve without hardware obsolescence. Researchers and engineers can upgrade specific modules to increase torque, add AI-driven sensing, or implement next-gen control algorithms — all while keeping the same base architecture intact.

In essence, OMY’s modular DNA turns a single robot into an entire ecosystem. From precision laboratory experiments to full-scale industrial automation, it’s a platform that grows with you — not one you outgrow.

Industrial Readiness and Safety

Active Safety at the Hardware Level

Each of OMY’s joints is powered by DYNAMIXEL-Y smart actuators—integrated systems that combine sensors, control logic, and communication into one intelligent module. These actuators continuously monitor their own torque, temperature, and load, enabling real-time detection of abnormal forces or contact. When necessary, OMY automatically transitions into a low-torque “safe mode” to prevent injury or mechanical damage.Multi-Layered Safety and Integration

OMY’s combined safety architecture—featuring hardware braking, torque monitoring, gravity compensation, and the E-stop—creates a robust fail-safe ecosystem. The modular, ROS 2-compatible control system allows integration with additional peripherals such as light curtains, proximity sensors, or vision-based monitoring systems. Together, these features make OMY an adaptable platform for collaborative automation, precision prototyping, and AI-driven robotics research.Physical AI and Advanced Learning Capabilities

OMY’s Leader-Follower configuration introduces a new era of Physical AI — allowing robots to learn complex manipulation tasks directly from human motion. Using this system, operators can physically guide OMY through actions, enabling the collection of high-quality demonstration data for imitation learning, reinforcement learning, and teleoperation experiments.

In Leader-Follower mode, one OMY robot (the Leader) is moved by a human operator while another OMY (the Follower) mirrors those motions in real time. This intuitive, hands-on teaching process allows robots to acquire motion skills safely and efficiently — ideal for policy learning, trajectory optimization, and adaptive control research.

With its sub-millimeter accuracy and 51 million-step encoder resolution, OMY captures detailed motion data across all six joints. Every movement, from subtle grip adjustments to full 6-DOF trajectories, can be recorded with precise timing and spatial accuracy. This enables machine learning models to train on real-world, high-resolution motion data far richer than typical sensor logs.

OMY bridges the gap between academic research and industrial automation. It supports reinforcement learning experiments, imitation learning studies, and human-robot collaboration testing in labs and then transitions seamlessly into real-world applications like assembly, inspection, and automated handling.

By combining high-fidelity sensing, precise actuation, and human-guided training, OMY serves as a flexible foundation for developing AI systems that don’t just think, they move, learn, and adapt in the physical world.

Integration in the ROBOTIS Ecosystem

OMY is more than a standalone manipulator — it’s a core part of the ROBOTIS ecosystem, a family of modular, intelligent robotics platforms designed to scale from educational research to industrial automation and humanoid systems.

OMY’s DYNAMIXEL-Y actuators are the same high-performance smart actuators used in the ROBOTIS AI Worker semi-humanoid platform. This cross-platform compatibility demonstrates the scalability and reliability of DYNAMIXEL technology — from precision manipulators to full-size humanoid robots operating in dynamic, real-world environments.

The lighterweight OMX arms utilize DYNAMIXEL-X actuators, offering a compact and accessible platform ideal for education, prototyping, and early-stage development. Together, OMY, OMX, and AI Worker systems form a continuum of modular robotics built on a common communication and software framework, including full ROS 2 compatibility. Engineers and researchers can design, test, and scale projects seamlessly across platforms, from a desktop research manipulator to a mobile humanoid robot, without changing the underlying actuator technology or control architecture.

This unified approach empowers users to explore every stage of robotics development within a single ecosystem from education and research to industrial deployment. Whether teaching AI models to grasp, move, or collaborate, ROBOTIS platforms share one modular, intelligent foundation.

Conclusion

The ROBOTIS OMY Leader-Follower Platform combines flexibility, durability, precision, and safety in a compact and modular design. Its DYNAMIXEL-Y actuators and cycloidal gear reduction provide the torque, repeatability, and reliability needed for both industrial and research environments. With modular components, easy maintenance, and AI-driven capabilities, OMY represents the next generation of robotic manipulators suitable for physical AI research, automation, and industrial applications. Learn more about OMY →